客户要求阳台要包括一个瑜伽区、聚会用餐区、舞池、工作区、15个座位、2个日光浴平台以及和广泛的绿色空间。单是所需的家具就占了600平方英尺,为了解决这一矛盾,每个家具都被设计成曲线的形状,并交叉放置在平台的表面,因此不同的层次的空间就此展开来,为一系列的活动提供了空间。

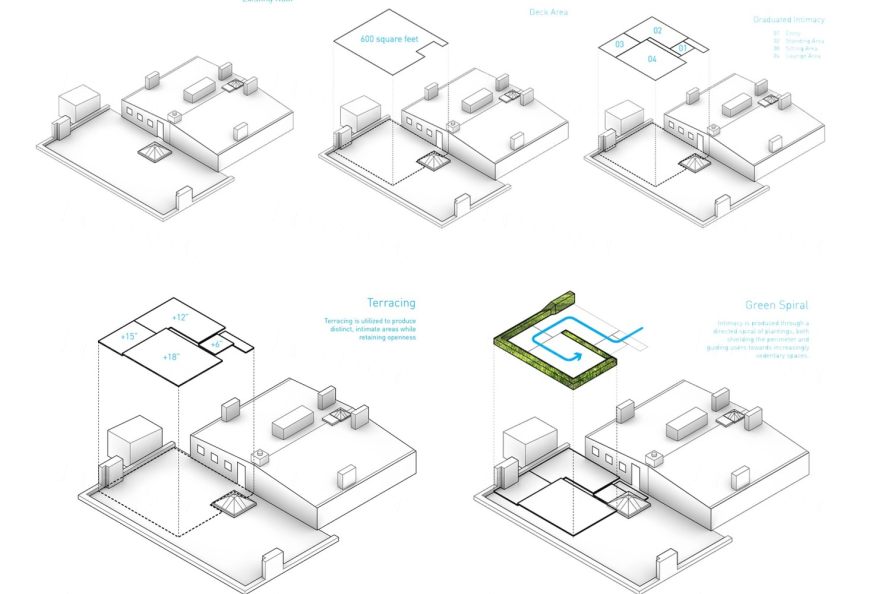

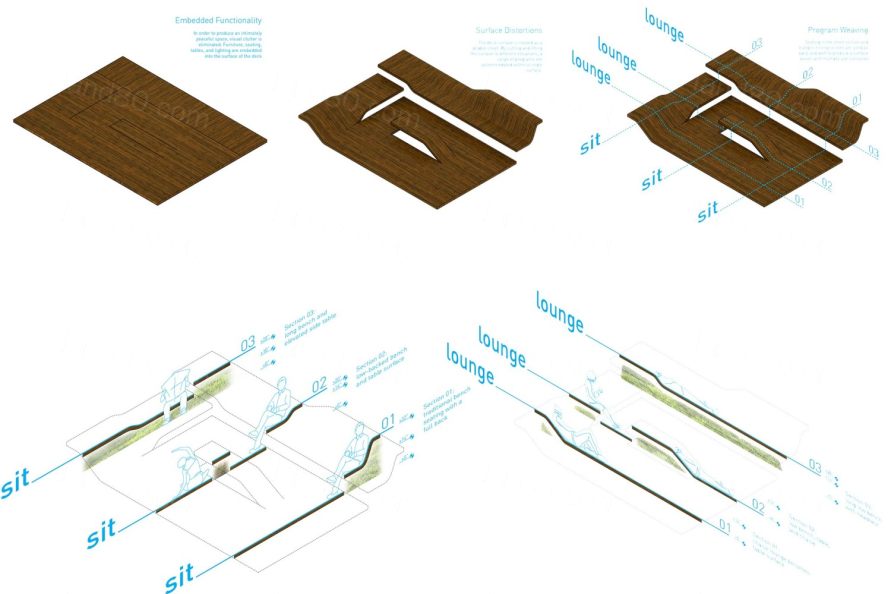

The client’s required program included a large and small yoga area, dining area for large and small parties, dance floor, shaded work area, seating for 15, sunbathing for 2, and extensive green space. The furniture required alone would have filled 600 square feet. In order to resolve this contradiction, programs are each assigned a curvature and are woven into the surface of the deck as warp and weft. Areas are sculpted up from the floor to various levels and angles of repose to produce terraced zones for a range of active to sedentary programs.

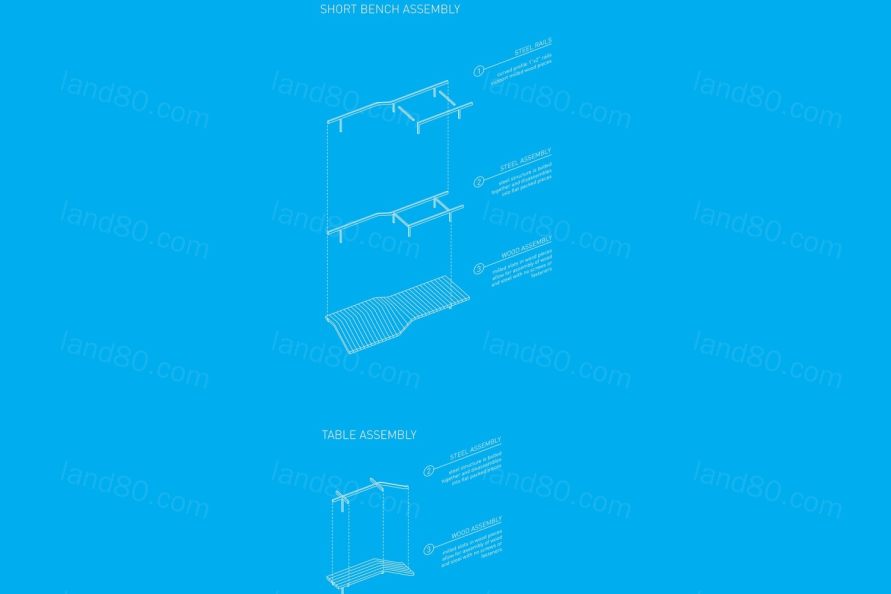

▼项目空间生成

▼在平面上设计曲线与高差,然后再相互交错,使得空间得以满足需求

由于场地位于历史街区,毗邻公园,太过于新颖的设计方案不太可能获得批准。为了满足规划需求和审批限制,屋顶平台就被视为一个完全模块化的家具组装,没有使用螺丝或钉子。所有家具都是可拆卸的,并且不附着在下面的表面上,使用传统的日本木结构将各个部分拼接在一起。这也满足了客户的另一个需求,能够方便的修复阳台,因为损坏的部件可以很容易地取出和更换,并在移动的情况下重新安装。

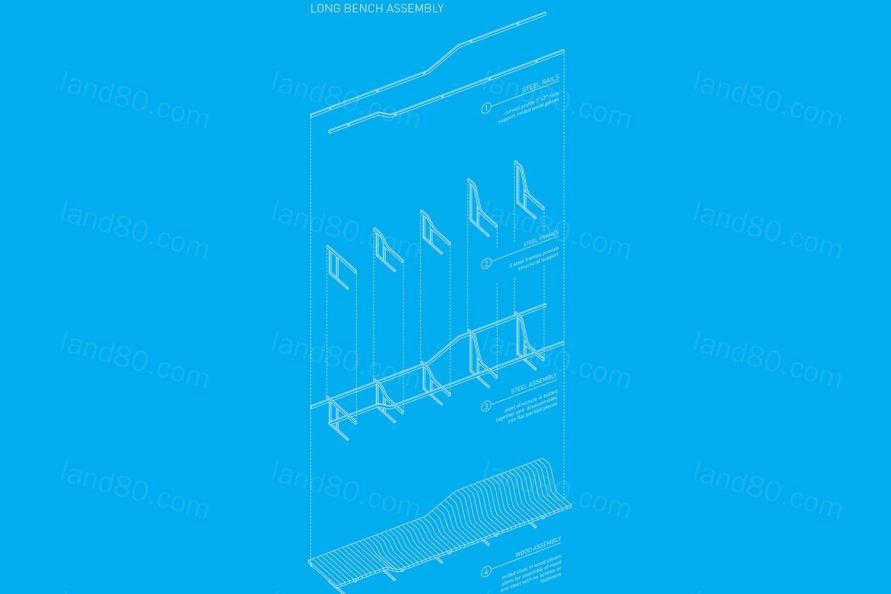

Due to the site’s location in a historic district and adjacent to a park, innovative design solutions were unlikely to be approved. To address both the programmatic need for fluid surfaces and approval constraints, the roof deck was treated as an entirely modular furniture assembly using no screws or nails, which sits atop a previously approved blank deck surface. The assembly is removable, and is not attached to the surface below. Instead, pieces slot together as with traditional Japanese wood construction. This also addressed the client’s desire to be able to repair the deck as damaged pieces could easily be popped off and replaced, and relocatable in the event of a move.

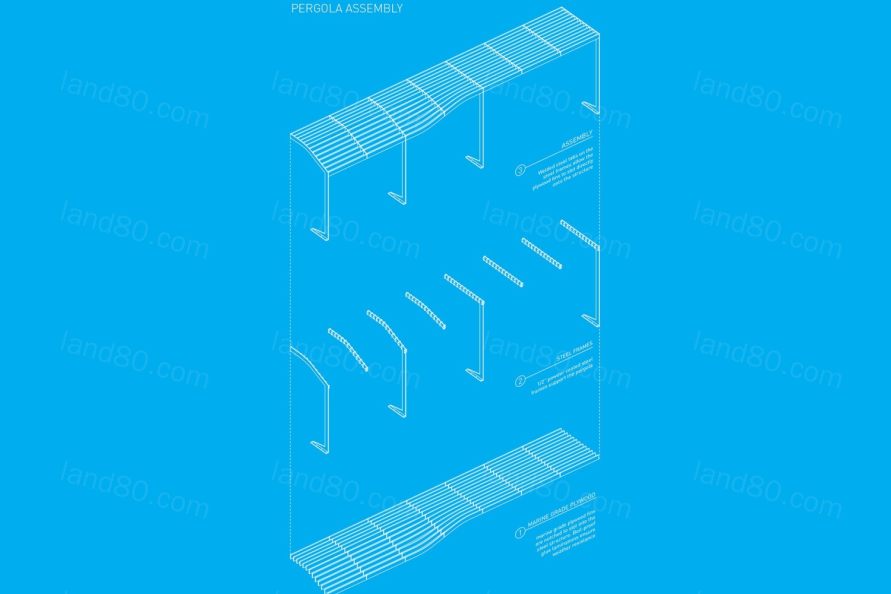

由于其耐腐性、可持续性、和易加工性和外观,Sapele木材被选为主要材料。日式的榫卯几何形状适用于数控铣削,作为坚固耐用的连接,以度过严酷的冬季。集成的沟槽和轨道也被数控加工成木片槽,支持模块金属框架和接收集成的LED照明。藤架是由海洋级Sapele胶合板板条。因此木材与和本地的草从、苔藓和多年生植被组成了一个易于维护和持久的花园。

Sapele was selected as the wood species used due to its rot resistance, sustainability, workability, and appearance. Japanese wood joint geometries were adapted for CNC milling and serve as robust, durable connections to last through harsh winters. Integrated grooves and tracks are also CNC milled into each wood piece to slot onto supporting modular metal frames and receive integrated LED lighting. A pergola was constructed out of marine grade Sapele plywood slats, and native grasses, mosses, and perennials were selected to provide a maintenance free and durable garden.

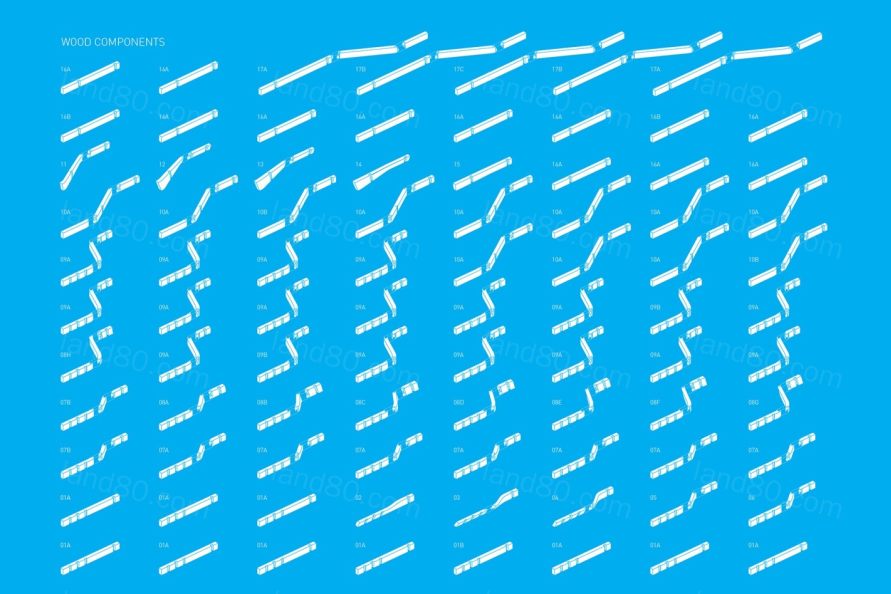

项目使用了16种独特的木材版型组成,以适应广泛的计划,使维修与更换容易。在其他地方,第二个同样屋顶平台项目正在使用相同的方法进行组装。

The project uses only 16 unique wood profiles to accommodate a wide range of programs, making repair/replacement easy. Modularity also allows for scalable mass customization. A second site-specific roof deck project is currently underway using the same components.

所有的设计工作、木工和安装都由建筑师完成。采用Polyfab数控铣削,种植与灌溉系统由Erdman Design设计完成。

All design work, carpentry, and install were performed by the architect. CNC Milling by Polyfab, steel fabrication by Atlantic Steel, planting and drip irrigation install by Erdman Design.

▼项目图纸

项目名称:Wood Flow

设计单位:J.Roc Design

项目位置:美国 波士顿

项目类型:屋顶平台 / 花园

面积:600平方英尺

预算:100,000美元(每平方英尺167美元)

Type: Roof Deck and Garden

Process: Design-Build (install and carpentry by architect, milling of components by others)

Size: 600 square feet

Budget: $100,000 ($167 per square foot)

Location: South End, Boston (Historic District)

|