布加纤维展亭,是斯图加特大学计算设计与结构研究所(ICD)和建筑结构与结构设计研究所(ITKE)多年建筑仿生学研究的基础上建立的,坐落在联邦花园的波浪状景观中,旨在让游客体验令人惊叹的建筑,一窥未来建筑的精妙。

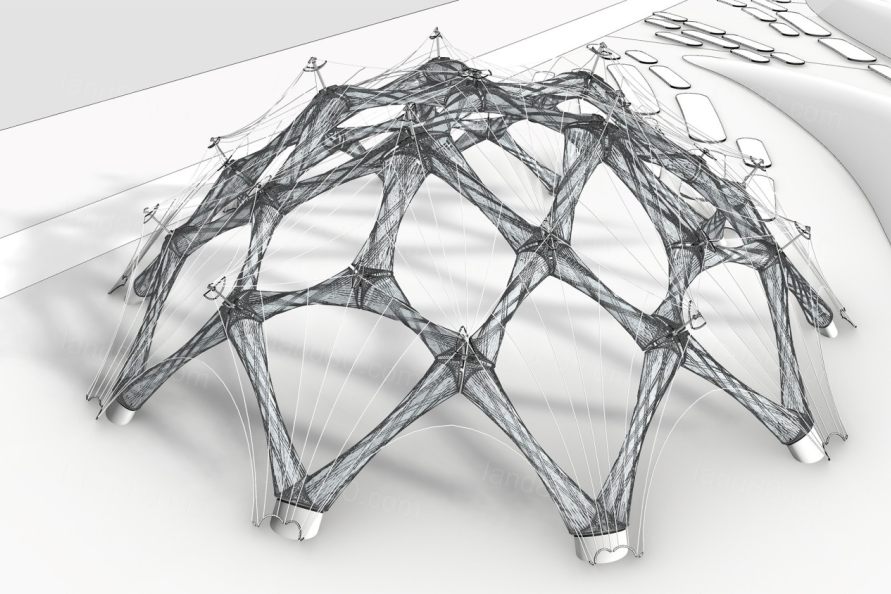

Embedded in the wavelike landscape of the Bundesgartenschau grounds, the BUGA Fibre Pavilion offers visitors an astounding architectural experience and a glimpse of future construction. It builds on many years of biomimetic research in architecture at the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE) at the University of Stuttgart.

▼Photos©:NIKOLAI BENNER

▼Photos©:NIKOLAI BENNER

项目展示了如何将尖端计算技术与建筑原理相结合,从而实现真正创新和数字化的建筑语言。承重结构由高科技纤维复合材料制备的,这种全球独一无二的结构不仅高效、轻盈,而且还营造了独特而真实的建筑表达和非凡的空间体验。

The pavilion demonstrates how combining cutting-edge computational technologies with constructional principles found in nature enables the development of truly novel and genuinely digital building system. The pavilion’s load-bearing structure is robotically produced from advanced fibre composites only. This globally unique structure is not only highly effective and exceptionally lightweight, but it also provides a distinctive yet authentic architectural expression and an extraordinary spatial experience.

▼Photos©:NIKOLAI BENNER

灵感来自大自然的新型复合建筑系统

在生物学中,大多数承重结构是纤维复合材料,例如纤维素、几丁质或胶原蛋白,以及支撑它们维持结构的基质,生物结构令人惊讶的性能和无可比拟的资源效率正源于这些纤维系统。生物的组织、方向性和密度都是精心调整的并且精细变化的,以确保材料只在需要的地方。

Novel composite building system inspired by nature

In biology most load-bearing structures are fibre composites. They are made from fibres, as for example cellulose, chitin or collagen, and a matrix material that supports them and maintains their relative position. The astounding performance and unrivalled resource efficiency of biological structures stems from these fibrous systems. Their organization, directionality and density is finely tuned and locally varied in order to ensure that material is only placed where it is needed.

▼Diagram©:ICD

布加纤维展馆旨在将负载相适应的生物原理和高度差异化的纤维复合系统应用到建筑中,这种方法非常适用于人造复合材料的建造,比如此建筑所用的玻璃纤维或碳纤维增强塑料,因为它们与天然复合材料具有相同的基本特性。

The BUGA Fibre Pavilion aims to transfer this biological principle of load-adapted and thus highly differentiated fibre composite systems into architecture. Manmade composites, such as the glass- or carbon-fibre-reinforced plastics that were used for this building, are ideally suited for such an approach, because they share their fundamental characteristics with natural composites.

▼Diagram©:ICD

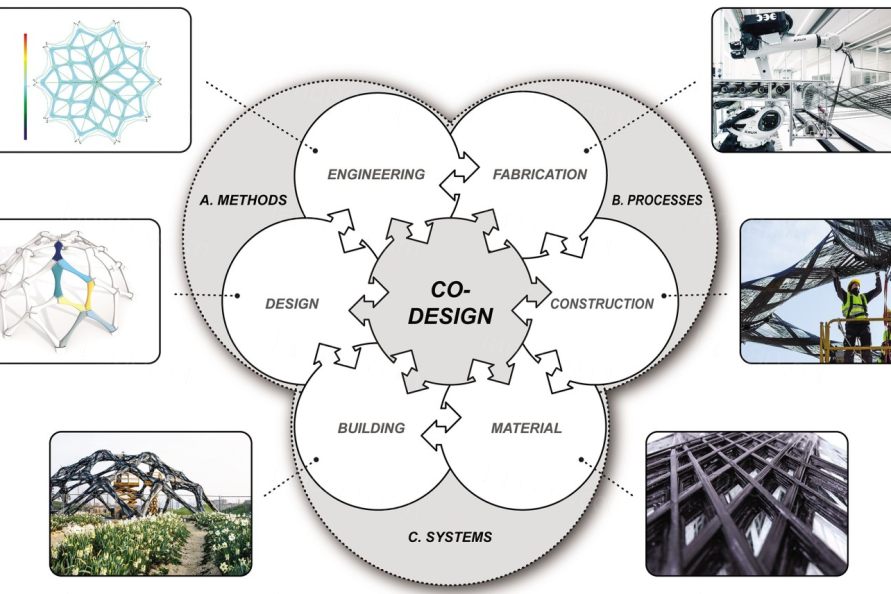

展亭的建造理论建立在计算设计与建造研究所(ICD)和建筑结构与结构设计研究所(ITKE)多年的仿生研究基础上,展示了跨学科的生物原理和最新的计算技术如何能建立一个真正创新和数字纤维复合构建系统。如果在几年前,这个项目是不可能建成的。

The project builds on many years of biomimetic research at the Institute for Computational Design and Construction (ICD) and the Institute for Building Structures and Structural Design (ITKE). It shows how an interdisciplinary exploration of biological principles together with the latest computational technologies can lead to a truly novel and genuinely digital fibre composite building system. Only a few years ago, this pavilion would have been impossible to design or build.

▼Photos©:ICD-ITKE

程序交互设计和机器预制

展亭是由超过150米空间排列的玻璃和碳纤维构成。每一个部分都需要单独设计和安装,传统的建造流程和安装是不可能完成的,因此,项目需要建立新的交互设计方法、设计思路、结构配比合机器预制,实现彼此连续的工作流和反馈。通过这种方式,每个建筑构件的纤维排列、密度和方向可以单独校准、结构调整和建筑铰接。

Integrative computational design and robotic fabrication

The pavilion is made from more than 150.000 meters of spatially arranged glass- and carbon fibres. They all need to be individually designed and placed, which is very hard to achieve with a typical linear workflow and established production technologies. Thus, it requires a novel co-design approach, where architectural design, structural engineering and robotic fabrication are developed in continuous computational feedback. In this way, the fibre arrangement, density and orientation of each building component can be individually calibrated, structurally tuned and architecturally articulated, while remaining directly producible.

▼Diagram©:ICD

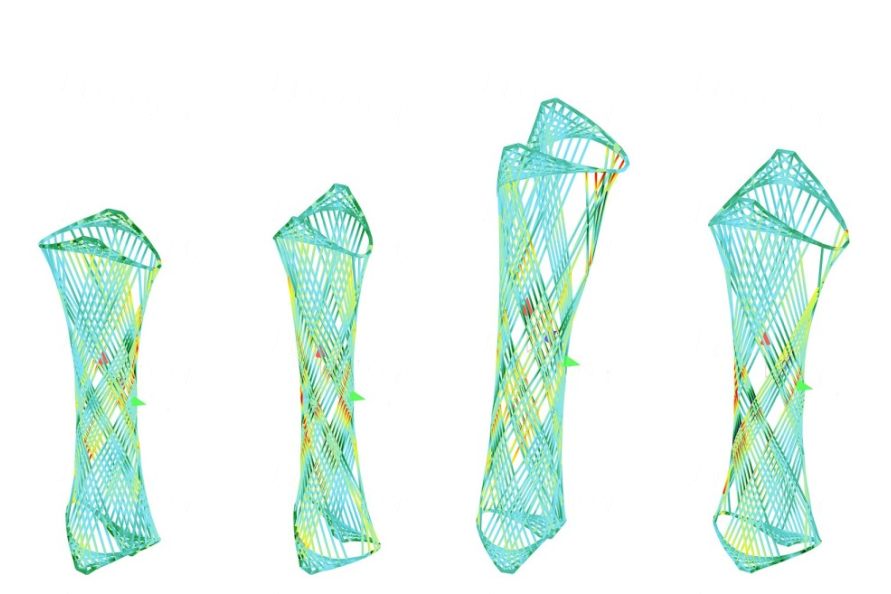

建筑构件由斯图加特大学首创的无芯纤维缠绕的机器人制造。纤维丝由机器人在两个旋转缠绕支架之间操作放置。在这个过程中,纤维丝浇筑了建筑构件的设计形状,因此不需要任何模具或型芯。这让单一定制形式和单独组件的纤维铺设不会带来造价上的高昂。此外,这个过程不产生任何生产废料或边角料。在制造过程中,有一个定位的半透明的玻璃纤维网格,黑炭玻璃纤维放在网格合适的位置。这造就了高负载相适应的建筑组件各不相同的的结构外观。

The building components are produced by robotic, coreless filament winding, a novel additive manufacturing approach pioneered and developed at the University of Stuttgart. Fibrous filaments are freely placed between two rotating winding scaffolds by a robot. During this process, the predefined shape of the building component emerges only from the interaction of the filaments, eliminating the need for any mould or core. This allows for bespoke form and individual fibre layup for each component without any economic disadvantage. In addition, there is no production waste or material off-cuts. During manufacturing, a lattice of translucent glass fibres is generated, onto which the black carbon fibres are placed where they are structural needed. This results in highly load-adapted components with a highly distinct architectural appearance.

▼Diagram©:ICD

▼Diagram©:ICD

项目的工厂合作伙伴FibR GmbH全面生产构件,每个构件平均需要4到6个小时,由1000米的玻璃纤维和1600米的碳纤维制成。

Full production took place at the project’s industrial partner FibR GmbH. Each component takes between four to six hours to make from around 1.000 meters of glass fibre and 1.600 meters of carbon fibre on average.

▼Photos©:ICD

独特的轻质结构和充满张力的建筑空间

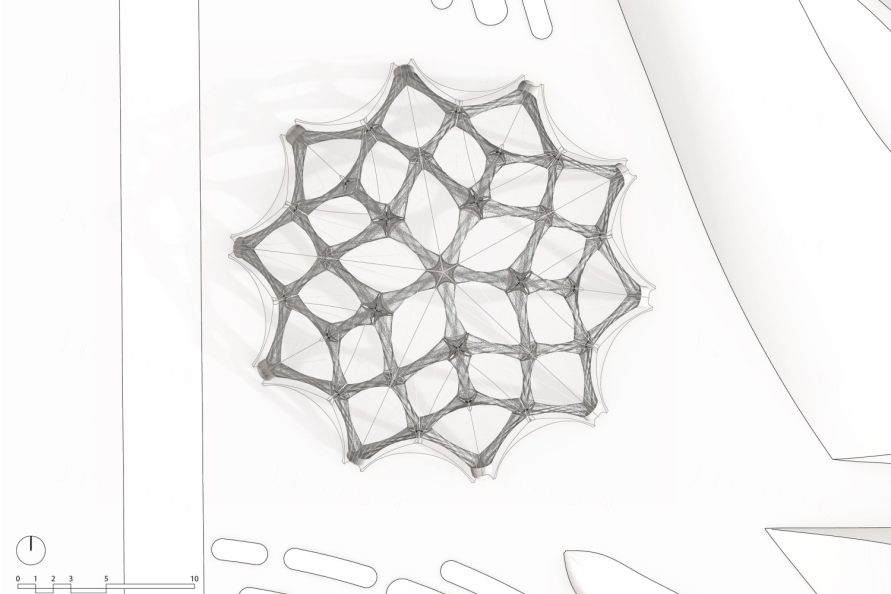

项目占地面积约400平方米,自由跨度超过23米。主要屋顶是全透明,机械预应力ETFE膜。主承重结构由60个定制的纤维复合材料组成。每平方米平均仅重76公斤,比传统的钢结构轻约5倍。方案的完整实现需要详尽全面的测试,用以证明仅纤维成分可以承受250公斤牛顿的压缩力,相当于25吨或超过15辆车的重量。展亭展示了真正的交互计算设计和机器预制的方法的可行性,使新型、数字纤维复合建筑系统的发展成为可能,这个工作流程完全符合严格的德国建筑法规,并且轻盈高效,形式感突出。

Unique lightweight structure and expressive architectural space

The pavilion covers a floor area of around 400 square meters and achieves a free span of more than 23 meters. It is enclosed by fully transparent, mechanically pre-stressed ETFE membrane. The primary load bearing structure is made from 60 bespoke fibre composite components only. With 7.6 kilograms per square meter it is exceptionally lightweight, approximately five times lighter than a more conventional steel structure. Elaborate testing procedures required for full approval showed that a single fibrous component can take up to 250 kilo newton of compression force, which equals around 25 tons or the weight of more than 15 cars. The pavilion shows how a truly integrative approach to computational design and robotic fabrication enables the development of novel, truly digital fibre composite building systems that are fully compliant with the stringent German building regulations, exceptionally light, structurally efficient and architecturally expressive.

▼Photos©:ICD-ITKE

黑碳纤维束包裹着半透明的玻璃纤维格,就像弯曲的肌肉一样,半透明轻盈的纤维网与结构的实形成了鲜明的对比。这种与众不同的建筑连接节点增强了从顶部到地面碳丝密度的梯度变化,在最薄的结构增大碳丝密度,与地面连接。虽然大多数游客从未见过这结构,但展亭以一种可理解而又富有表现力的方式展示了它的基本设计原则。不常见但果断的建筑表达将会引起数字建造的新浪潮,这不再是未来主义的主张,而是已经成为可见现实。

Embedded in the wavelike landscape of the Bundesgartenschau grounds, the pavilion translates the innovation on a technical level into a unique architectural experience. The black carbon filament bundles, wrapping around the translucent glass fibre lattice like flexed muscles, create a stark contrast in texture that is highlighted by the pavilion’s fully transparent skin. This distinctive architectural articulation is further intensified by the gradient from sparser carbon filaments at the top towards their denser application on the slenderest components that meet the ground. While most visitors may not have seen anything like it before, the pavilion exposes its underlying design principles in an explicable yet expressive way. Its unfamiliar yet authentic architectural articulation evokes new ways of digital making, which no longer remain a futuristic proposition but already have become a tangible reality.

▼Photos©:ICD-ITKE

布加纤维展亭落地联邦花园夏季岛屿中心,并参加Zukunftskarusell展览。巴登符腾堡州州长参加了2019年4月17日的开幕式。斯图加特大学的优秀学者们将深入探讨关于纤维构件建造体系的“建筑交互计算机设计与建造”课题。

The BUGA Fibre Pavilion is centrally located on the Summer Island of the Bundesgartenschau 2019 and will house the exhibition “Zukunftskarusell”. It will be opened on 17th of April 2019 by the Minister President of the State of Baden-Wuerttemberg. The research on fibre composite building systems and structures will be further pursued in the context of the new Cluster of Excellence “Integrative Computational Design and Construction for Architecture” at the University of Stuttgart.

▼Photos©:ICD-ITKE

▼Photos©:NIKOLAI BENNER

▼总平面图 Diagram©:ICD

▼平面图 Diagram©:ICD

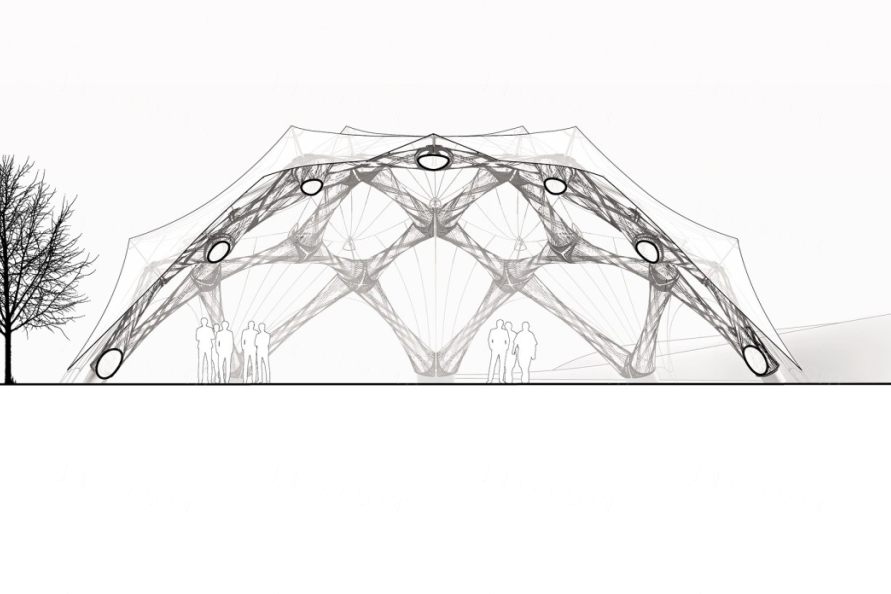

▼剖面图 Diagram©:ICD

项目团队:

ICD – Institute for Computational Design and Construction,

University of Stuttgart

Prof. Achim Menges, Serban Bodea, Niccolo Dambrosio, Monika Göbel, Christoph

Zechmeister

ITKE – Institute of Building Structures and Structural Design,

University of Stuttgart

Prof. Jan Knippers, Valentin Koslowski, Marta Gil Pérez, Bas Rongen

FibR GmbH, Stuttgart

Moritz Dörstelmann, Ondrej Kyjanek, Philipp Essers, Philipp Gülke

Bundesgartenschau Heilbronn 2019 GmbH

Hanspeter Faas, Oliver Toellner

建造团队:

Landesstelle für Bautechnik

Dr. Stefan Brendler, Dipl.-Ing. Steffen Schneider

Proof Engineer

Dipl.-Ing. Achim Bechert, Dipl.-Ing. Florian Roos

DITF German Institutes of Textile and Fiber Research

Prof. Dr.-Ing. Götz T. Gresser, Pascal Mindermann

资金赞助:

Land Baden-Württemberg

Universität Stuttgart

Baden-Württemberg Stiftung

GETTYLAB

Forschungsinitiative Zukunft Bau

Pfeifer GmbH

Ewo GmbH

Fischer Group

Project Partners

ICD – Institute for Computational Design and Construction, University of Stuttgart

Prof. Achim Menges, Serban Bodea, Niccolo Dambrosio, Monika Göbel, Christoph Zechmeister

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Prof. Jan Knippers, Valentin Koslowski, Marta Gil Pérez, Bas Rongen

FibR GmbH, Stuttgart

Moritz Dörstelmann, Ondrej Kyjanek, Philipp Essers, Philipp Gülke

Bundesgartenschau Heilbronn 2019 GmbH

Hanspeter Faas, Oliver Toellner

Project Building Permit Process

Landesstelle für Bautechnik

Dr. Stefan Brendler, Dipl.-Ing. Steffen Schneider

Proof Engineer

Dipl.-Ing. Achim Bechert, Dipl.-Ing. Florian Roos

DITF German Institutes of Textile and Fiber Research

Prof. Dr.-Ing. Götz T. Gresser, Pascal Mindermann

Project Funding

Land Baden-Württemberg

Universität Stuttgart

Baden-Württemberg Stiftung

GETTYLAB

Forschungsinitiative Zukunft Bau

Pfeifer GmbH

Ewo GmbH

Fischer Group

Project Data

Dimensions

23m diameter, Covered Area: 400.0m², Weight of loadbearing fibre composite structure: 7,6kg/.0m²

Construction System

60 load bearing robotically fabricated glass- and carbon fibre composite elements, out of 150.000m glass- and carbon fibres; transparent, mechanically pre-stressed ETFE membrane

|