功能与空间的剥离

Separation of function and space

地产营销中心在完成销售后,多数时候会被拆除,使用时间长则几年,短则数月,是一种非常“短命”的建筑类型;少数时候保留下来也将被完全更改使用性质,它的内部空间一般装修繁复,在功能改造过程中也会带来极大的改造难度和资源浪费。

Real estate marketing center is a kind of temporary architecture that can only last several months or few years at most, which is usually dismantled after houses are sold out. Even if it can be preserved in few cases, functions are completely transformed. Interior decoration of real estate marketing centers is generally complicated, causing obstacles and waste of resources in the process of functional repurposement.

如何创造一种空间,满足暂时的营销功能,又具有广泛的其他使用可能,是最合适的切入点,与其说是在设计营销中心,不如说是设计一个没有功能约束的空间来得更恰当。

The building not only meets the temporary need of marketing but also has potential for a wide range of other possible usages. It’s more appropriate to say that we designed a space without functional constraints rather than just a marketing center.

延深些的思维逻辑就是将(空间限定性强)楼梯、卫生间等必要的服务空间按照人体工学做成基本模块,其他的(空间限定性弱)被服务空间尽可能弱化属性,达到一种功能与空间的剥离,获得空间使用上的绝对解放。

We turned all necessary service spaces featuring great spatial restrictions such as staircase and bathroom into basic modules in accordance with Ergonomics, and meanwhile tried our best to weaken the functional attribute of other remaining spaces. In this way, we separated function and space, so as to eliminate functional constraints of spaces.

常规木材的最大木构空间单元&可生长

Utilization of general timbers to maximize the pace and make it extensible

客户是鲜有的对地产开发有着极高品控的农场主,不盲目追求快速商业利益,而是通过营造更好的生活方式去吸引置业者,除了普通的地产开发也一直在进行着生态农场的打造和运营,也希冀通过营销中心传达给受众一种绿色生活方式的体验。

The client is an estanciero who pursues high quality of real estate development instead of instant commercial profits. Based on the concept of attracting house buyers through creating a better lifestyle, he has been devoted to operating eco-farms as engaging in property development. A green lifestyle is exactly what he wants to convey to target consumers through the marketing center.

无疑,木料成为了最佳的建筑主材。它是绿色材料,体现了与自然的连接,非常贴合客户的企业气质。

Timbers, the green and natural materials that suite the client's corporation identity, are undoubtedly the most perfect materials for constructing the building.

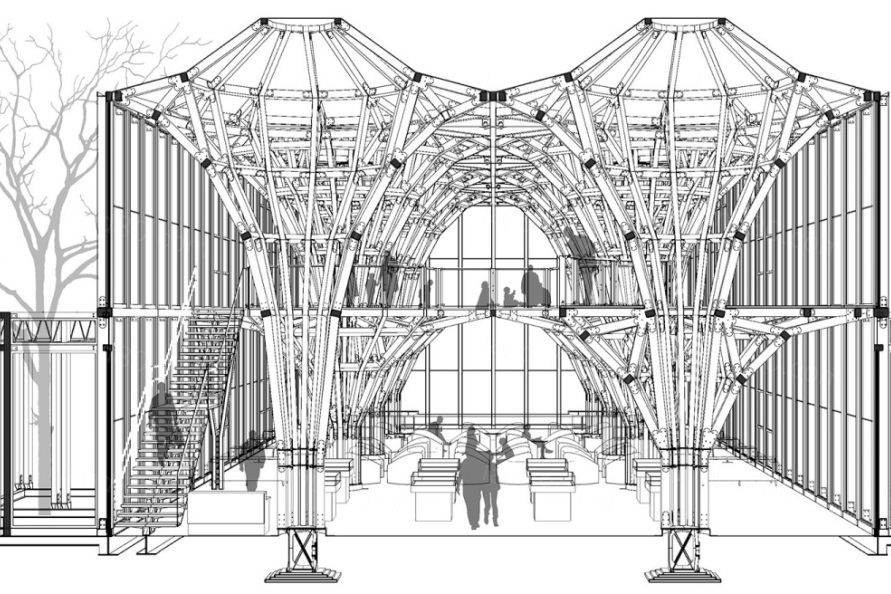

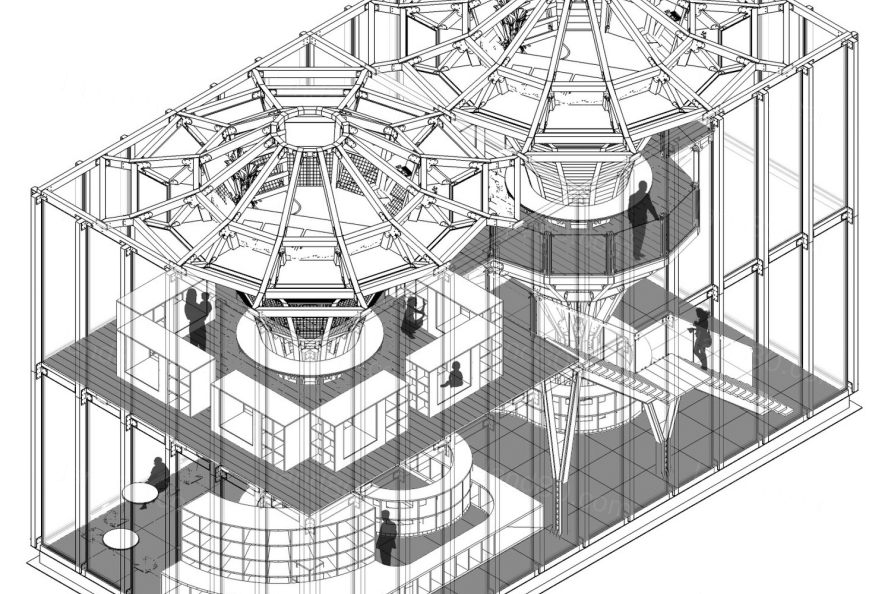

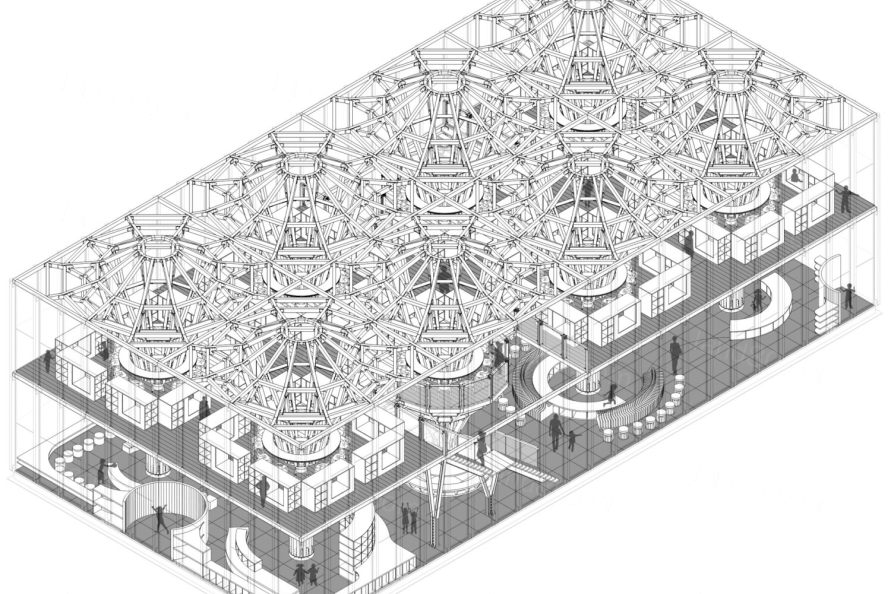

可以采购到高性价比的常规木材尺寸为:3m、4m、6m长,横截面200mm左右的方料。如何运用这些基准木料,去搭建一个大空间,获得更多元的空间适用可能。单根木柱为独立支撑单元是不太合适的,因为得不到一个无柱的大空间状态。以多根木柱组合形成“集束柱”是比较合适的选择。在自然应力里,圆形受力最均衡,根据单柱截面尺度、适宜高度、便捷施工空隙等因素,水平单元形态采用了近圆形的正12边形、直径1m、木截面120mm*180mm的集束组合柱。垂直方向采用 “树”的生长形态,分成五段每段2m左右,由内向上也向外慢慢挑出生长,最终形成高度4.5m、边长8m的方体边界空间,这样下部达到了使用的相对最大空间,整体又得相对最大结构强度。

Cost-effective general timber materials that we could purchase were square logs in the length of 3m, 4m or 6m, with a 200mm side length of the cross-section. To build a large solid space and maximize its possible functions, several square timber pillars were combined together to form a “clustered column” instead of using a single wooden pillar as the supporting unit. As forces acting on circle plane are even in different directions, horizontal units of the clustered column were designed in the shape of regular dodecagona, which are nearly round, with a diameter of 1m. As for vertical units design, we applied the shape of trees. The clustered column was divided into five segments, each with the length of about 2m. These segments extend outward and upward to the ceiling, forming a cubic edge space with a height of 4.5m and a side length of 8m. With such clustered columns, we not only maximized the lower space but also the structural strength.

单元结构“集束柱”底部是正多边形,为了形成自由拼接之间的无空隙,底部向上延申由一开始中心的“近圆形”最后生长成外边界的“正方形”基本单元空间,正方形外边界单元体彼此可以任意在水平向X轴或Y轴上连续生长拼接,这些单元就像乐高积木一样,可以独立存在、也可以两个及以上到N个的组合,去获得所需要的空间尺度,它是可完全生长的。单元与单元之间水平对接又形成“连续拱券”,是一种结构非常稳定的受力体系,越生长结构越稳定。

The bottom part of each "clustered column" is in the shape of regular polygon. These "clustered columns" extend upward from the bottom and form a "square" outside edge. Each unit along the edge was horizontally and longitudinally interlined. Just like Lego bricks, each unit is independent or combined with others to create the desired space. The space is extensible. With “continuous arch” between each unit, the overall structure is very stable. And the more it stretches, the more stable the structure is.

基本建造手段下的极速装配&可逆性

Rapid assembling via basic construction methods & reversibility

由于各种客观因素,要求设计、施工、装修、配饰在两个月的时间内完成,同时还要控制在低造价,并且可以快速搭建拆装、反复使用。对设计者来说既是挑战,也是重要的限制条件。

We were asked to complete design, construction, finishing and decoration of the architecture in less than two months and at the same time control the cost, meanwhile, the architecture was required to be reusable that could be quickly constructed and dismounted. For us, it was a great challenge.

解决的策略是:

1,采取最基本的建造方式、用最普遍的材料加工工艺、让普通技术工人就可以参与建造、在最常见的工厂就可以加工生产,控制人工和工艺的低价和高效,达到工程可快速建造的状态。

2,最大程度的标准化、模块化,从整体拆分为基本单元,再拆分为标准部件,最后可以只是由三个基本部件构成,控制了最小和最少模块单元,建立一套标准简洁的组装逻辑,得以在各个施工和安装阶段加快速度。

3,拆分所有可能细分的工种,尽可能分在不同的工厂加工,并合理配置生产车间,必要时进行距离和空间、设备上的再调配。所有的材料和部件不用到工地现场等待前序工作完成再进行下一步施工。如放线挖槽的同时,钢构的基础在金属工厂加工,木柱在木作工厂加工,钢连接构件在数控车床加工…基础安装就位,土方回填的同时在钢构基础上安组装好的单元木柱组合部件。只需要将部件之间的构件进行螺栓连接即可。甚至包括室内的家具、空调、地面、线路系统..。所有的工序统筹进行。最终使得建施和软装控制在49历天的时间内,提前完成了不可能完成的工作。

We offered the following solutions.

Firstly, trying best to control labor cost and improve efficiency. we adopted simple and basic construction methods as well as common material processing techniques, through which ordinary technical workers were capable of carrying out the construction work and materials could be processed in common factories, which ensured the building to be constructed in a short time.

Secondly, ensuring the standardization and modularization of units. We divided the whole building into several primary units. And these primary units were further splitted into various standard components which were assembled based on a unified approach. The minimum unit could be formed only by three basic components, which was conductive to controlling the size and number of modular units. Besides, we established a set of standard and simple approaches for assembling, so as to accelerate the construction and installation process.

Thirdly, subdividing all types of work involved in the project as much as possible, processing materials in different factories, and arranging manufacturing workshops reasonably. In this way, all materials and components could be processed before or while the pre-order work on site was carried out. For example, while measuring and grooving work was carried out at the site, components of the steel structure, wooden columns and steal connection components were processed in different factories separately. After back-filling was finished, wooden column units were assembled on the basis of the steel structure. All wooden column units were interlinked through bolting steel connection components. And all relevant work such as installation of indoor furniture, air conditioning and wiring systems was carried out in a coordinated way. Eventually, we completed construction and decoration of the building ahead of schedule.

整座建筑除了一层地面考虑到诸多现实使用因素采用了水泥砂浆铺贴地砖外,其他所有的部件都采用的是螺栓连接,所有的组成构件都可以被拆卸,进行再施工利用,不用担心场地被征用需要拆除而完全无法移走使用的困境,哪怕是基础,也是可以完全拆卸和安装的。这是一个可完全移动并重复被使用的“长寿”建筑,达到了一种可逆建造状态。

Considering various practical factors, we laid tiles on the ground floor by using cement mortar. However, all other parts in the space were connected by bolts. All components can be completely dismounted, installed, moved and reused for other constructions, making the building thoroughly reversible.

构建一个“智慧”的生命腔体

Construction of a “smart” cavity

如果把建筑拟生化,所需要的设备、机电、管线就是生命体所相对应的呼吸系统、经络、血脉..,生命体是如此的智慧,所有这些系统它们绝不是孤立存在的,而是和骨架、肌肉腱体高度契合嵌在一起,是一种共生的状态,得到一个更有效、更集约的腔体。

If the building is a person, all the equipment, electromechanics, pipelines of it are the respiratory systems, collaterals and blood vessels of the body. All these systems in the body are by no means isolated, but are highly integrated with the skeletons and muscles in a symbiotic state, resulting in a more effective and intensive space.

本项目附属物的营造方式,就是遵循生命体的构建智慧。如家具,就采用了从结构体自然生长而成的方式,桌子与“集束柱”各单体木柱组接,家具“长”在结构柱上,所有的围护栏杆也是长在结构体系上。可以这么说,最核心的结构树,就自然生长出了家具、护栏,甚至向外生长织出外表皮,同时这些必须的“零部件”因为是主结构体伴生的关系,也会反作用于结构体而协同受力使得结构更稳定。

Other parts of the building were also designed in a way similar to the structure of body. Taking furniture as example, all the furniture “grows” on the structural column, with each table surrounding a single “clustered column”. All the furniture and guardrails stretch out of the core structure, and even weave a surface by extending outward. These necessary parts are concomitants of the main structure, providing support against it and making it more stable.

设备、机电、管线、家具、外表皮等融合到结构单元或者结构体系之中。达到的效果就是这些附属内容占据最小的空间,使功能与空间剥离的目标更好的实现,得到一个“智慧”的类生命腔体空间。

Equipment, electromechanics, pipelines, furniture and exterior were integrated into units of the structure to achieve the smallest occupancy, which facilitated separation of function and space and created a "smart" space resembling cavity of the human body.

普适空间&普用空间

Universal space&universally-used space

密斯·凡·德·罗将芝加哥伊利诺伊理工学院克朗楼称为“普适空间”, 因为设计允许建筑改变功能,密斯称“它是创造的最清晰的建筑,完美地体现了普适的理念”。

Mies van der Rohe called the Crown Hall at the Illinois Institute of Technology in Chicago a “universal space”. The design permits the building to change its functions, so Mies declared it “the clearest structure we have done, the best to express our philosophy.”

珑府生活体验中心以国内现有的常规标准木材和普遍性加工工艺、建造技术,并不是迁就和设计某个特定功能,而是创造无限的使用可能,包含但不限于密斯的“普适空间”的是,在空间不变而达到功能“普适”的基础上,还可以根据不同的时间变化、适用状态而去增加、删减、更替或移动建筑的局部或整体。它本身也可以完全被拆分消解,通过“可逆建造”重回到材料的初始状态为其他建筑施工行为所用,达到一种空间和材料都能普遍运用的最大可能。

As designing and constructing the Longfu Life Experience Center, we chose to use standard timbers in China and utilized common processing and construction techniques, with a view to create a “universal space” that boasts infinite possible usages rather than be limited to a certain specific function. The building is a “universal” space, but more importantly it is a “universally-used space”. The whole building or any part of it can be enlarged, cut, replaced or moved based on different needs. What’s more, it can also be completely dismounted and repurposed, and its materials can be reused for other constructions, hence achieving the objective that both the space and materials can be most universally used.

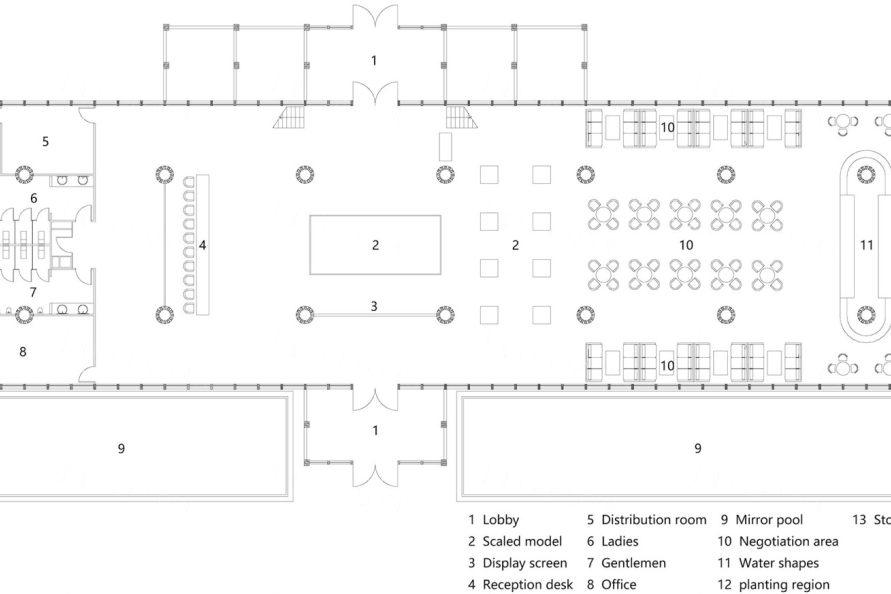

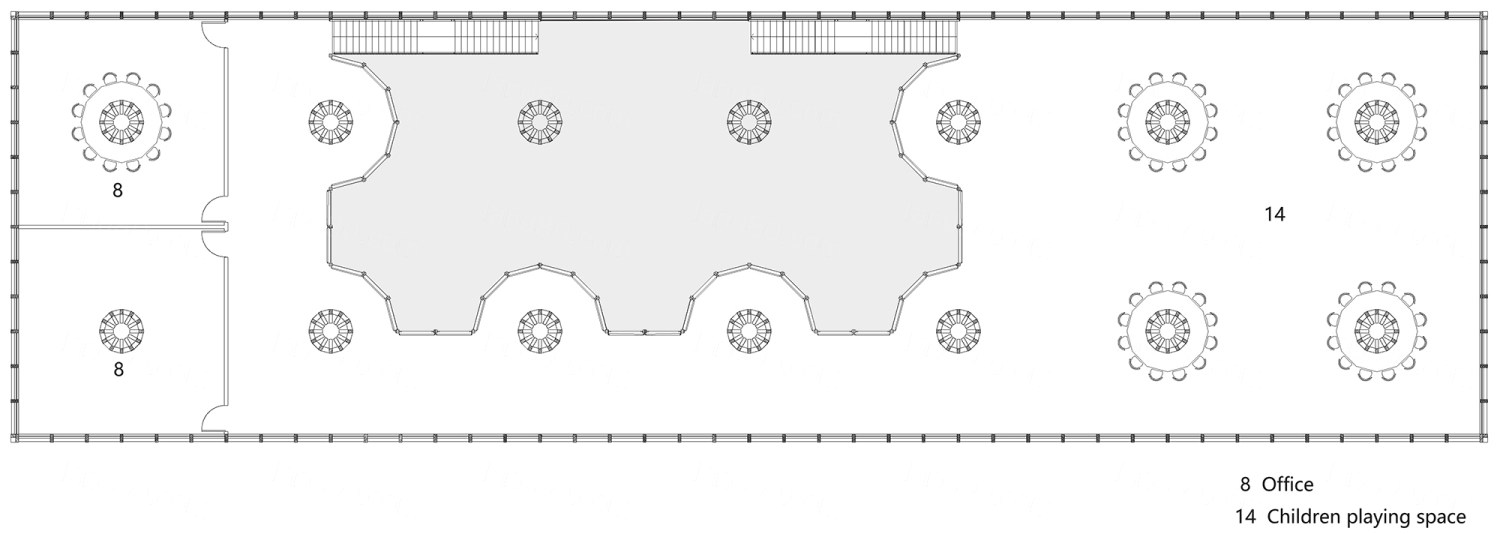

项目图纸:

LUO studio │罗宇杰工作室

主创建筑师:罗宇杰

参与设计人:王小涛 魏文景

业主(设计顾问):来利军

施工负责人:贾明忠

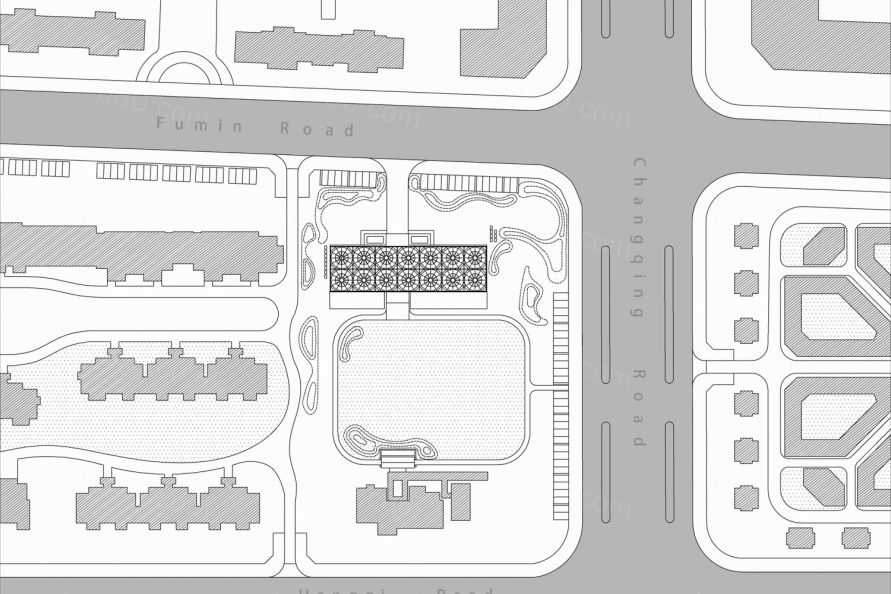

项目地址:中国河南省濮阳县长庆路与富民路交叉路口西南

建筑面积:1588平方米

建筑摄影师:金伟琦

设计时间:2018年1月25日

竣工时间:2018年4月10日(材料加工、现场施工49工作日)

Project name: Longfu Life Experience Center----a universally-used space created by general timbers and techniques

Design team:

Studio: LUO studio

Chief designer: Luo Yujie

Participating designers: Wang Xiaotao, Wei Wenjing

Owner (crediting):Lai Lijun

Construction team:Jia Mingzhong

Metal processing company: Henan Zhongyuan Antai New Energy Equipment Co., Ltd. (former ZYZJ Petroleum Equipment Co., Ltd.)

Project Location: Southwest of the intersection of Changqing Road and Fumin Road, Puyang County, Henan Province, China

Architecture area: 1588 m2

Photographer: Jin Weiqi

Design date: January 15, 2018

Completion date: April 10, 2018 (49 workdays in total for material processing and on-site construction)

|